Airbag

Our deep-drawn parts are increasingly utilized in cold gas generators of airbag systems, representing another significant application within the automotive sector that transcends vehicle propulsion types. As the number of airbags in vehicles rises, so does the demand for deep-drawn components. Leveraging our expertise in producing these pre-formed components with side recesses and apertures seamlessly integrated into the transfer tool, we enhance the efficiency of the end products for our customers.

Sector: Automotive

Sensor Technology

One of the key focuses of our product portfolio is the manufacturing of housings and protective sleeves for sensors used across various applications, including wheel rotation detection and steering angle control. With the growing importance of electronic driver assistance systems, the demand for highly precise sensor technology continues to rise steadily. As a result, the production of high-precision, thin-walled deep-drawn parts for these applications now represents a significant portion of our manufacturing output.

Sector: Automotive

Electromagnetic Drives

The use of electric drives, such as actuators and motors, in vehicles has seen significant growth in recent years. This trend is further accelerated by the ongoing development towards electromobility and intelligent assistance systems. At our company, we specialize in manufacturing deep-drawn components for electric motors of various geometries and dimensions, focusing particularly on high-precision production of thin-walled sleeves. These components pose specific challenges for internal and external parts logistics and packaging. Through close collaboration with our customers, we develop effective solutions that prioritize both quality and cost-efficiency.

Sector: Automotive

Fastening Technology

In the field of fastening and attachment technology, components are characterized by their high strength, intricate geometry, and high demand quantities. Thanks to the process-specific cold hardening, precise process reliability, and efficient manufacturing methods, deep-drawn parts are ideally suited for producing components for these applications.

Sector

: Automotive

Roll Bearing Components

A traditional segment of our product portfolio includes sleeves and rings for rolling bearing technology. These are mainly support, retaining, and sealing rings with sophisticated geometry. Some of these parts undergo a hardening process. The production of heat-treated, thin-walled drawn parts requires specialized expertise, as thermal distortion must be anticipated when determining the part geometry.

Sector: Automotive

Control And Regulation Technology

In electromechanical, pneumatic, and hydraulic actuators and valve systems, deep-drawn parts are often a cost-effective, high-quality alternative to turned parts. Especially for high volumes, they offer attractive technical and economic solutions. Through close collaboration with our customers and considering value analysis, we have frequently succeeded in efficiently replacing cost-intensive, machined components with deep-drawn parts.

Sector: Automotive

Powertrain

Our manufacturing includes the production of sleeves for the drivetrain of passenger cars, which are used in various applications. These include the valve train of the engine, the release bearing of the clutch, and the dual-clutch transmission.

In addition to our expertise in deep drawing, we also offer the necessary heat treatment processes. The production of hardened, thin-walled deep-drawn parts poses a special challenge, which we have continuously improved and finally perfected over the years.

Sector: Automotive

Locking Systems

We manufacture large quantities of deep-drawn caps and assembled components for a globally operating market leader in security and locking systems. Here, functionality is just as important as aesthetic design. We provide our customers with fully assembled products featuring sophisticated surface designs, including laser-printed logos. These components are used in electronic locking systems for medium-sized and large-scale real estate projects. The timely introduction of this technology for use in residential properties is expected to significantly increase demand.

Sector: Non-Automotive | Safety

Lighting

Over recent years, lighting technology has undergone significant transformations, largely due to the emergence of LED technology. Traditional components are being phased out in favor of innovative alternatives. As LED technology advances rapidly and the demand for cost-effective solutions increases, inexpensive deep-drawn parts are playing an increasingly vital role in this sector.

Sector: Non-Automotive | Lighting

Control And Regulation Technology

In any application where signals are transformed into motion, drive and motion elements are indispensable. For such applications, we manufacture deep-drawn parts that enable our customers to achieve cost-effective end products. Our forming technology enables an ideal harmonization of functionality, quality, and efficiency.

Sector: Non-Automotive | Control And Regulation

Heating Technology

As heating and heat technology undergoes digitalization, the demand for deep-drawn components is on the rise. Our precise products are utilized not only in the main components of heat generation but also in peripheral systems such as pumps and pipelines.

Sector: Non-Automotive | Heating Technology

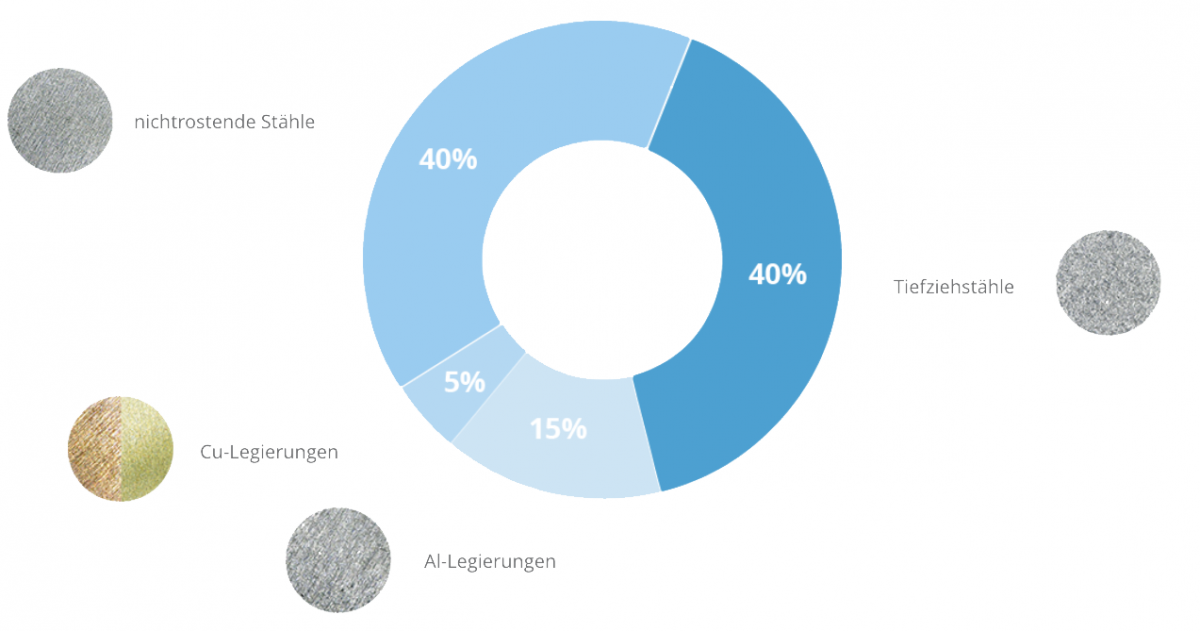

Materials

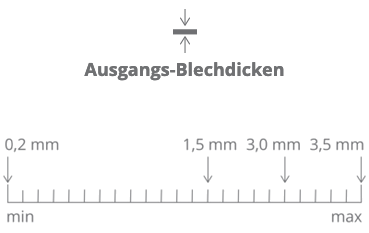

We work with all materials suitable for deep drawing, including steel, stainless steel, aluminum, and copper alloys. Additionally, unconventional materials such as titanium or high-alloy nickel steels can be formed without cutting. Our spectrum of raw materials also includes coated strips (Zn, Sn, Ni, etc.).